The evolution of technological and natural systems does not always follow a linear path of performance improvement. A fundamental principle of innovation is the harmonization of rhythms among the parts of a system through coordination and de-coordination. This concept applies to various fields, from mechanics to biology, from engineering design to social organization.

The Paradox of Military Marching

A striking example of this principle is military marching. Soldiers marching in unison create a spectacular visual effect, but when crossing a bridge, this coordination can be dangerous. The resonance phenomena generated by synchronized marching can compromise the structure’s stability, potentially leading to its collapse. To prevent this risk, soldiers are ordered to walk freely when crossing a bridge, thus applying the principle of dynamic de-coordination to ensure safety.

Coordination and De-coordination in Technological Systems

The principle of rhythm harmonization is widely used in technological design to enhance system performance and mitigate undesirable effects.

1. Cutting Tools and Vibrations

Cutting tools with multiple blades perform better when the cutting teeth are not perfectly symmetrical. If each blade were positioned at equal intervals, the system would generate (resonant) vibrations, compromising efficiency and tool lifespan. By introducing slight angular variations between the teeth, resonance is avoided, improving operational stability.

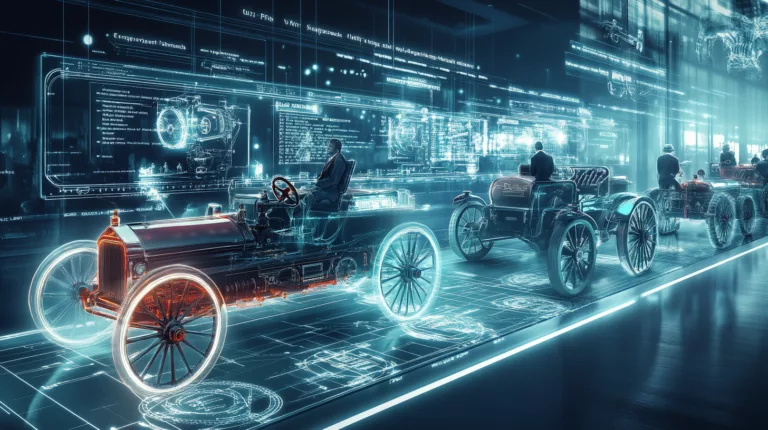

2. Evolution of Wheels in Traction Systems

The evolution of wheels in transportation shows various applications of this principle:

- Uncoordinated elements: A tractor with front wheels and rear tracks combines components with differentiated functions.

- Coordinated elements: Modern automobiles use four identical wheels to ensure stable and uniform driving.

- De-coordinated elements: Drag racing cars adopt small front wheels and large rear wheels to improve traction and speed.

- Dynamic coordination and de-coordination: High-end cars adjust the front wheel steering angles independently to enhance road grip in curves.

Applications in Industrial and Manufacturing Processes

Many companies aim to reduce variability in production processes through statistical process control (SPC), but excessive reduction of variability can have negative effects. For example, in manufacturing industries, excessive symmetry in product components can reduce performance. A good example is engine design, where varying ignition phases in cylinders improves smooth operation and reduces unwanted vibrations.

Other industrial examples include cooling systems in power plants, where de-coordination of fluid flow reduces the risk of overheating. Similarly, in additive manufacturing (3D printing), internal material structures can be arranged in a way that prevents stress buildup and ensures greater structural strength.

Coordination and De-coordination in Biology and Nature

Numerous examples of this principle can be found in nature:

- Heartbeat: The human heart does not always beat at a perfectly regular frequency but adapts its rhythm to meet the body’s metabolic needs.

- Bird flock flight: Migratory birds do not fly in a perfectly symmetrical formation but adjust their distance and position to reduce air resistance and conserve energy.

- Plant growth: Some plants regulate root growth differently to adapt to heterogeneous soil conditions, optimizing water and nutrient distribution.

In the animal kingdom, fish schools use de-coordination to evade predators, while in living cells, synchronized and desynchronized circadian rhythms help optimize metabolism and response to external stimuli.

Rhythm Harmonization in Social Organization

This principle also applies to social and corporate dynamics. Companies operating globally must balance coordination among different branches with the necessary de-coordination to adapt to local markets. For example, lean assembly lines leverage the principle of rhythm harmonization to maximize productivity without creating bottlenecks.

Another example is urban traffic management: if all traffic lights followed a perfectly coordinated rhythm, congestion could occur at certain points. For this reason, traffic control systems use de-coordination algorithms to optimize flow and reduce gridlocks.

Conclusion

Rhythm harmonization through coordination and de-coordination is a key strategy in technological and natural evolution. Understanding how to modulate these principles allows for improved system efficiency, reduced negative resonance effects, and optimized product and process performance. By applying these principles, we can design more effective solutions in engineering, industrial production, and biology while ensuring greater sustainability and superior performance. Moreover, this concept extends to social organization and business process management, demonstrating how coordination and de-coordination can create efficiency and adaptability in complex systems.